Observation Tower Introduction and Its Application

Overview

An observation tower is a tall structure designed to provide a vantage point for viewing the surrounding landscape. These towers are commonly used in various settings, including parks, nature reserves, urban environments, and industrial sites, to enhance visibility and facilitate activities such as wildlife observation, sightseeing, and surveillance.

Key Features

- 1. Height: Typically ranges from several meters to over 30 meters, allowing for expansive views.

- 2. Material: Constructed from durable materials such as wood, steel, or concrete, ensuring stability and longevity.

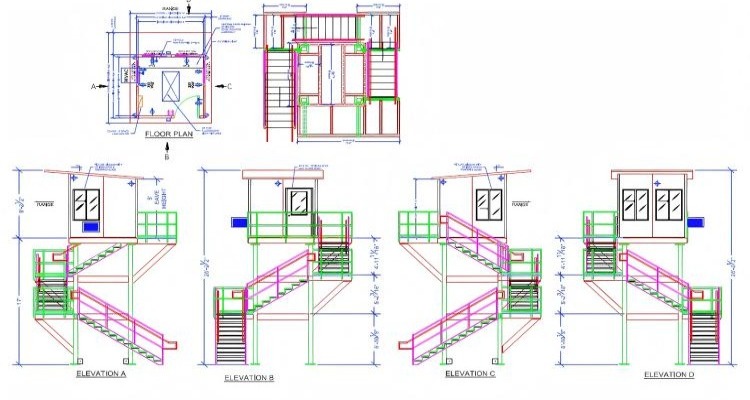

- 3. Design: Can vary in architectural style, from simple platforms to elaborate structures with enclosed viewing areas.

- 3. Access: Equipped with stairs, elevators, or ladders for safe and easy access to the observation deck.

Applications

- 1. Tourism: Enhances visitor experiences in parks and scenic areas by providing breathtaking views.

- 2. Wildlife Observation: Allows nature enthusiasts to observe wildlife without disturbing their habitats.

- 3. Urban Surveillance: Used in city planning and security to monitor public spaces and events.

- 4. Research: Serves as a platform for environmental studies and data collection in various ecosystems.

Benefits

- 1. Enhanced Visibility: Offers unobstructed views, making it easier to spot objects or events from a distance.

- 2. Community Engagement: Can serve as a focal point for community activities and events, promoting local tourism.

- 3. Educational Opportunities: Provides an ideal setting for educational programs related to ecology, geography, and urban planning.

Conclusion

Observation towers are valuable structures that enhance the ability to view and appreciate the surrounding environment. Whether for recreational, educational, or security purposes, they play a significant role in connecting people with nature and improving community engagement.

Learn more at www.alttower.com