Electron Paramagnetic Resonance Brands In South Korea

Electron Paramagnetic Resonance (EPR) spectrometers are widely used in research institutions, universities, and industrial laboratories in South Korea. Major brands of EPR spectrometers in Korea include Jeol, Bruker, Nicolet, and CIQTEK. Below are the features and prices of these EPR companies.

Jeol

Features: Jeol is a time-honored brand known for its high-quality and reliable instruments. On the downside, the cost is relatively high compared to other brands. In addition, depending on the specific model, their instruments may have limited flexibility regarding modular configuration and specialized accessories.

Bruker

Features: Bruker is a well-known EPR spectrometer company. Their spectrometers are known for their high sensitivity, advanced signal processing capabilities, and ruggedness. However, it is costly and the complexity of the instrument software may require a learning curve for new users.

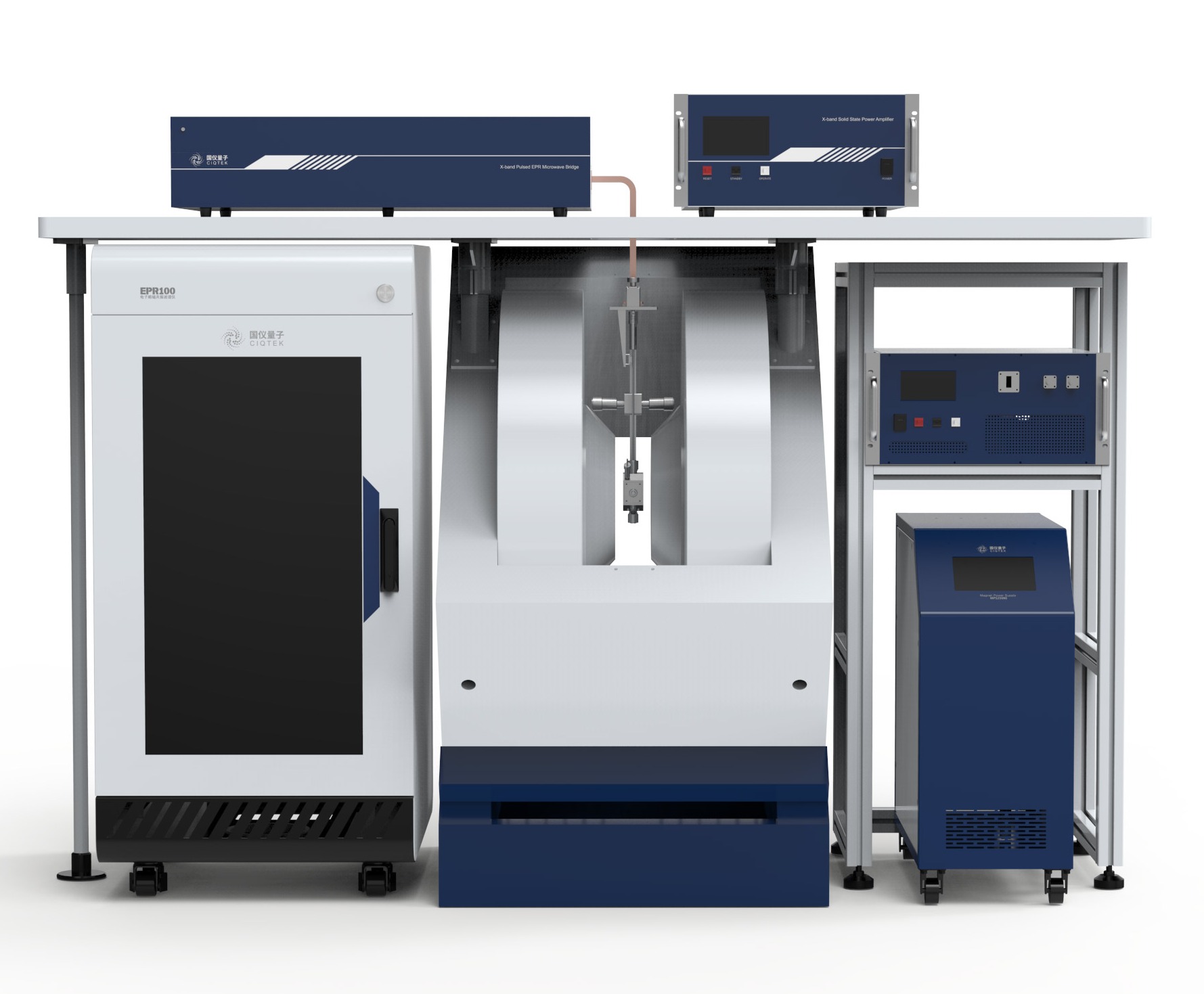

CIQTEK

CIQTEK EPR spectrometers are technologically advanced with world-leading resolution and sensitivity. Also featuring a user-friendly software interface that is easy to use for beginners, CIQTEK's wide range of EPR spectrometers is equipped with a variety of specialized accessories and options for versatility in experimental setups. It is more affordable. Saves time and budget.

Nicolet (Thermo Fisher Scientific)

Features: Nicolet EPR spectrometers from Thermo Fisher Scientific are renowned for their accuracy, reliability, and ease of use, with excellent signal-to-noise ratios and sensitivity for a wide range of EPR applications. They have excellent signal-to-noise ratios and sensitivity for a wide range of EPR applications. One potential drawback of Nicolet EPR spectrometers compared to other brands is their limited availability of specialized accessories and options, which may limit certain experimental setups or specific research needs.

![]()

It's worth noting that the prices mentioned above are rough estimates and can vary depending on the specific configuration and region. Additionally, each brand may offer different models with varying specifications and price ranges.