The Revolution of Multihead Weighers in the Food Packaging Industry

In the world of food packaging, accuracy, speed, and efficiency are crucial elements for success. To meet these demands, the industry has witnessed the rise of a remarkable technology called the Multihead Weigher. It has revolutionized the way products are weighed and packaged, offering unparalleled precision and productivity. In this blog post, we will delve into the workings of multihead weighers and explore their impact on the food packaging industry.

What is a Multihead Weigher?

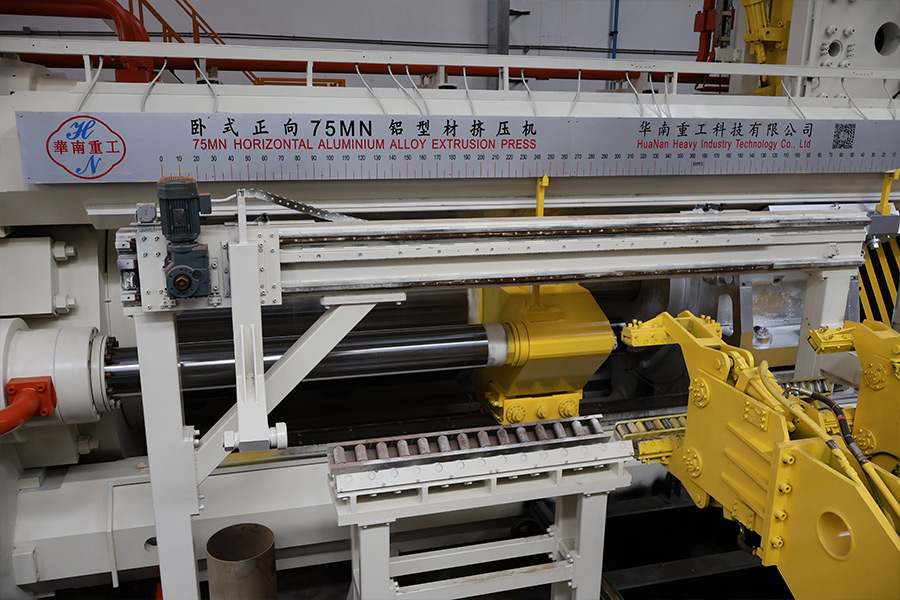

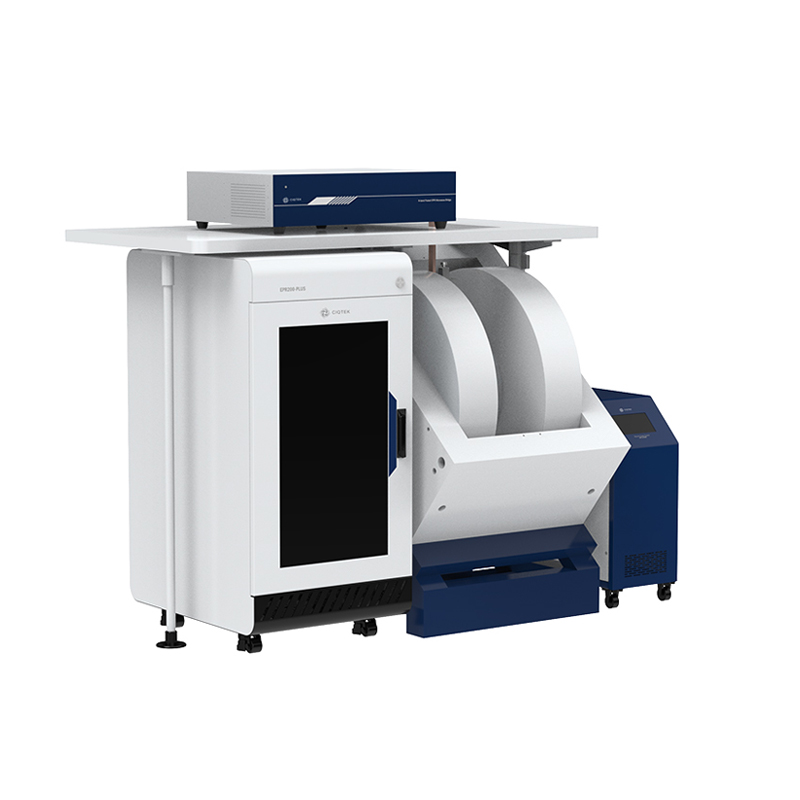

A Multihead Weigher is a cutting-edge weighing system that employs advanced technology to accurately measure and distribute a wide variety of food products. It consists of several independent weighing heads, each equipped with its own load cell. These heads work together in synchronization, allowing for high-speed weighing and packaging operations.

How does it work?

The multihead weigher operates through a three-step process: weighing, calculation, and distribution. First, the product is fed into the multihead weigher, where it is divided into individual portions by the weighing heads. Each head simultaneously measures the weight of its designated portion using load cells and sends the data to a central processing unit.

Next, the central processing unit calculates the optimal combination of portions to achieve the desired target weight. It configures the distribution paths to ensure the accurate allocation of portions, taking into account factors such as the characteristics of the product and the packaging requirements.

Finally, the calculated portions are distributed to the packaging machine, which fills the individual packages rapidly and precisely. This seamless process ensures that each package contains the correct weight, minimizing product giveaway and maximizing efficiency.

Advantages of Multihead Weighers:

Precision: Multihead weighers are renowned for their exceptional accuracy, even with complex products like mixed nuts, snacks, or frozen foods. This accuracy results in consistent product quality and customer satisfaction.

Efficiency: With their high-speed weighing capabilities, multihead weighers significantly increase productivity. They can handle large volumes of product, reducing production time and labor costs.

Versatility: Multihead weighers are adaptable to various food product types, sizes, and shapes. They can handle both dry and wet products, making them suitable for a wide range of applications in the food packaging industry.

Hygiene and Food Safety: Multihead weighers are designed with food safety in mind. They feature smooth surfaces and removable parts for easy cleaning, promoting hygiene standards and reducing the risk of contamination.

Impacts on the Food Packaging Industry:

The integration of multihead weighers has had a transformative effect on the food packaging industry. It has brought about increased operational efficiency, improved packaging quality, and reduced product waste. The precise weighing and distribution capabilities of multihead weighers have also enabled manufacturers to meet stringent regulatory requirements and maintain compliance with industry standards.

Furthermore, the automation and speed provided by multihead weighers have facilitated streamlined production processes. This has allowed companies to scale their operations, penetrate new markets, and meet the growing demand for packaged food products.

Conclusion:

The advent of multihead weighers has revolutionized the food packaging industry, offering unparalleled accuracy, efficiency, and versatility. As technology continues to advance, we can expect further enhancements in multihead weighers' capabilities, enabling manufacturers to meet evolving consumer demands and achieve greater success in the competitive market.

Whether it's ensuring the consistent weight of a bag of chips or accurately portioning delicate confectionery treats, multihead weighers will continue to play a crucial role in the future of food packaging.