Types of Generators Commonly Used to Power COWs

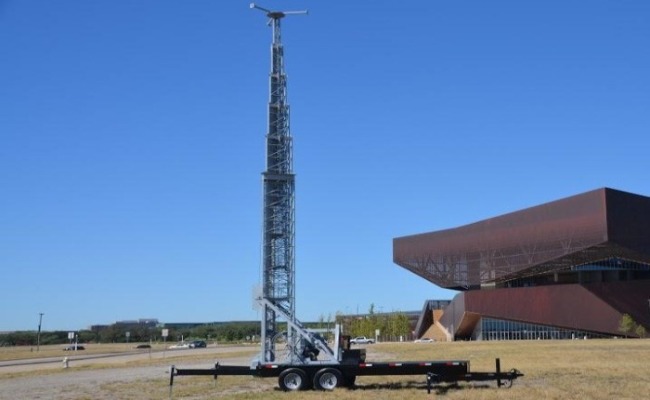

Cellular on Wheels (COWs) are typically powered by generators to ensure continuous operation and provide temporary cellular network coverage in various situations. The types of generators commonly used to power COWs include:

1. Diesel Generators:

- Advantages: Diesel generators are robust, reliable, and efficient, making them suitable for continuous operation over an extended period.

- Fuel Availability: Diesel fuel is commonly available and can be stored for extended periods, making it a practical choice for remote or emergency deployments.

- Power Output: Diesel generators can provide high power output levels, which may be necessary to support the equipment and antennas on a COW.

2. Gasoline Generators:

- Advantages: Gasoline generators are more portable and lighter compared to diesel generators, making them easier to transport and set up in various locations.

- Fuel Availability: Gasoline is readily available, but it can be less efficient and may require more frequent refueling compared to diesel.

- Power Output: Gasoline generators are suitable for powering smaller COW setups or in situations where portability is a priority.

3. Natural Gas Generators:

- Advantages: Natural gas generators are cleaner-burning and more environmentally friendly compared to diesel or gasoline generators.

- Fuel Availability: Natural gas supply infrastructure may limit the deployment of natural gas generators in certain locations.

- Cost-Effectiveness: In areas where natural gas is readily available, using natural gas generators can be cost-effective.

4. Propane Generators:

- Advantages: Propane generators offer a clean-burning fuel source that is readily available in portable cylinders or tanks.

- Fuel Storage: Propane can be stored for long periods without degradation, making it suitable for backup power applications.

- Versatility: Propane generators are versatile and can be used in various locations where propane fuel is accessible.

5. Hybrid Generators:

- Advantages: Hybrid generators combine multiple fuel sources, such as diesel and solar, to provide power flexibility and increase efficiency.

- Fuel Efficiency: Hybrid systems can optimize fuel consumption based on power demands, leading to cost savings and reduced environmental impact.

- Renewable Energy Integration: Some hybrid generators incorporate renewable energy sources like solar power to reduce reliance on traditional fuels.

The choice of generator for powering a Cellular on Wheels (COW) system depends on factors such as power requirements, fuel availability, portability, environmental considerations, and specific deployment scenarios. Diesel generators are commonly preferred for their reliability and high power output, especially in situations requiring continuous operation and high energy demand.

Learn more at www.alttower.com