Why is a leveling casters with a handle more convenient?

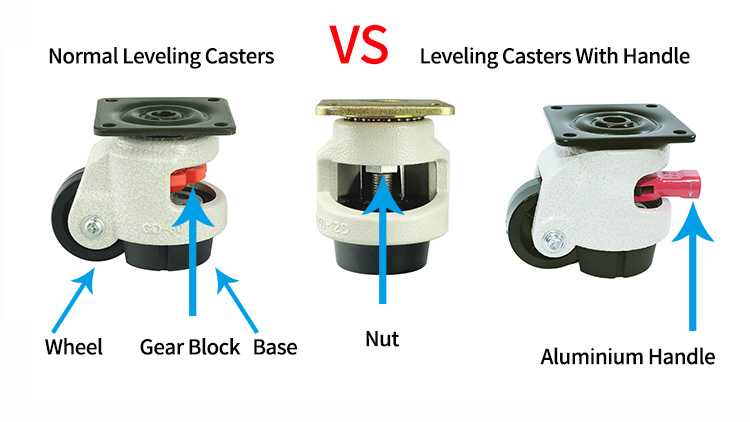

Why is the leveling casters with handle more convenient to use than the ordinary one? We all know that the ordinary leveling wheels is to extend or lift the base by rotating the gear block or nut on the central axis screw rod, so as to control the movement and locking state of the caster. The base is lifted, retracted into the caster bracket, the wheels touch the ground, and the assembled machine or equipment enters a movable state. When moved to the proper position, the gear or nut is turned in the opposite direction, the base is extended downward, the wheels are lifted off the ground, and the machine or equipment cannot be moved again. The space for this operation is generally limited, so the operation of the ordinary level adjustment wheel is relatively inconvenient, especially when heavy objects are pressed on it.

Why is a leveling caster with foot pedal more convenient? We all know the principle of arch rods, the same object, when the fulcrum is fixed, the longer the rod, the less force required to pry the object. Handles are much longer than both gears and nuts and require less force. And it usually sticks out of the heavy duty leveling casters housing, and the operating space is larger. And the end of the handle is also equipped with a round hole, if necessary, you can use other small rods to insert the extended arch rod, which is more labor-saving.